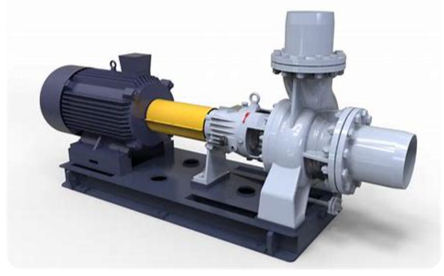

Cooling pumps are an indispensable part of industrial systems,The stability and efficiency of its performance are crucial to the overall operation. In this segment,The role of sensors is particularly prominent,They are like the "eyes" and "ears" of the cooling pump,Real time monitoring of pump working status,Ensure stable operation of the cooling system.

Below, Let's explore it detail the application of sensors in cooling pump technology work and related technical indicators

First,Flow rate sensor is an indispensable sensor in cooling pumps,It is mainly used to monitor the flow rate of coolant,Ensure that the pump can operate according to the predetermined flow requirements,Application of flow sensors,It can help us find clogs or leaks in the cooling system in time,To avoid a decrease in heat dissipation efficiency caused by insufficient flow.

secondly,The pressure sensor is also one of the common sensors in the cooling pump.It monitors pressure changes in the cooling system in real time,Make sure the pump is working within the specified pressure range.Pressure sensor applications,N,ot only can prevent equipment damage caused by too high or too low pressure,It can also improve the stability and reliability of the cooling system.

In addition,Temperature sensors are also widely used in cooling pumps. It can monitor the temperature of the coolant in real time,Provide accurate temperature signals for the control system.Through the application of temperature sensors,We can achieve precise control of the temperature of the cooling system,Ensure that the pump is operating within the optimum operating temperature range ,Thereby improving cooling efficiency and service life.

In addition to the above common sensors,There are other types of sensors that are also used in cooling pumps.Such as,The level sensor is used to monitor the coolant level,Ensure that the pump operates under normal liquid level conditions ;

Vibration sensors are used to detect the vibration of pumps,Prevent equipment failures caused by excessive vibration.

In terms of technical indicators, the application of sensors in cooling pumps mainly focuses on the following aspects:

Measurement accuracy:The sensor needs to be able to accurately measure the parameters of the cooling pump,Such as flow, pressure and temperature.High precision measurements ensure the stability and reliability of the cooling system.Response speed:The sensor needs to be able to respond quickly to changes in the working state of the cooling pump,In order to take corresponding control measures in a timely manner,Fast response speeds reduce the risk of equipment failure and improve cooling efficiency.

Reliability:The sensor needs to have high reliability,Sensors need to have high reliability and be able to maintain stable performance over long periods of operation.Meanwhile, sensors also need to have certain anti-interference capabilities to cope with complex working environments.

Compatibility:The sensor needs to be compatible with the cooling pump's control system to enable seamless data transmission and processing.This ensures that the overall performance of the cooling system is fully utilized.

in summary,Sensors play a crucial role in the technical work of cooling pumps.They monitor the various parameters of the cooling pump in real time,Ensure stable operation of the cooling system, improve equipment lifespan and efficiency.At the same time, with the continuous development of technology,In the future, more new sensors will be applied to cooling pumps,Provide more efficient and stable cooling solutions for the development of the industrial sector.