In the fields of power systems, industrial automation, new energy equipment, etc., leakage current sensors are like loyal "current guardians", always guarding the safety of equipment and personnel. When the equipment experiences insulation damage or other faults, the leakage current sensor can sensitively capture abnormal currents, issue timely alarms, and avoid safety accidents. Next, let's delve into the working principle of leakage current sensors.

Electromagnetic induction leakage current sensor

The operation of electromagnetic induction leakage current sensors is based on Faraday's law of electromagnetic induction. Under normal circumstances, the current in the circuit flows through the wires, generating magnetic fields that cancel each other out, and the external detection coil does not generate induced electromotive force. However, when leakage occurs, the current no longer follows the original closed loop path, and some of the current will leak through abnormal paths (such as between the equipment casing and the ground). At this point, the original current balance is disrupted, and the magnetic flux passing through the detection coil changes. According to Faraday's law of electromagnetic induction, an electromotive force is induced in the detection coil, resulting in induced current. By detecting and processing the induced current, the presence and magnitude of leakage current can be determined.

Taking the common household leakage protection switch as an example, it integrates an electromagnetic induction leakage current sensor inside. When someone accidentally touches the casing of an electrical device, causing current leakage to the ground, the sensor detects the imbalance of the current and quickly triggers the protection switch to cut off the power supply in a very short time, ensuring personnel safety.

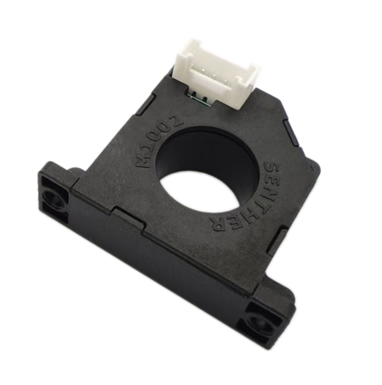

Hall effect leakage current sensor

The core of a Hall effect leakage current sensor is the Hall element. Hall element is a magneto electric conversion device based on the Hall effect. When a current passes through the Hall element, if a magnetic field is applied perpendicular to the direction of the current, a voltage difference will be generated on both sides of the Hall element, which is called the Hall voltage. In a leakage current sensor, the magnetic field generated by the measured current is applied to the Hall element. The magnitude of the Hall voltage generated by the Hall element is proportional to the strength of the magnetic field generated by the passing current, and the strength of the magnetic field is related to the magnitude of the current. Therefore, by measuring the Hall voltage, the magnitude of the leakage current can be indirectly obtained.

The Hall effect leakage current sensor has the advantages of fast response speed, high accuracy, and good linearity, and is widely used in the battery management system of electric vehicles. During the operation of electric vehicles, Hall effect leakage current sensors monitor the leakage current of the battery system in real time. Once an abnormality is detected, an alarm is immediately issued to prevent serious accidents such as fires caused by leakage in the battery system.

Magnetic modulation leakage current sensor

The working principle of magnetic modulation leakage current sensors is relatively complex. It utilizes the characteristic of the magnetic permeability of the magnetic core changing with the excitation current to detect leakage current. The sensor is equipped with an excitation coil and a detection coil inside. The excitation coil generates a periodically changing excitation magnetic field, causing the magnetic core to periodically change between saturated and unsaturated states. When there is no leakage current, the magnetic flux change of the magnetic core is symmetrical, and no induced electromotive force is generated in the detection coil. When a leakage current passes through, the magnetic field generated by the leakage current will be superimposed on the excitation magnetic field, breaking the symmetry of the magnetic flux changes in the magnetic core, thereby generating induced electromotive force in the detection coil. By analyzing and processing the induced electromotive force, the magnitude and direction of the leakage current can be determined.

Magnetic modulation leakage current sensors have strong anti-interference ability and high accuracy, and are commonly used in industrial detection and power systems that require high accuracy. For example, in large substations, they are used to monitor the leakage current of high-voltage equipment and ensure the stable operation of the power system.

The above introduces the common working principles of leakage current sensors. Different types of sensors are suitable for different scenarios. If you want to learn about their applications in specific industries or are interested in their technological development, please feel free to let me know.