一、 Introduction

In the field of sensor technology, the piezoresistive effect, as a unique physical phenomenon, provides a highly sensitive solution for measuring physical quantities such as pressure, stress, acceleration, etc. Piezoresistive sensors have become indispensable sensing components in modern industries, aerospace, biomedical and other fields due to their excellent performance. This article will start from the microscopic mechanism of piezoresistive effect, and deeply explore the working principle, technical characteristics, and engineering applications of piezoresistive sensors.

二、 Microscopic mechanism of piezoresistive effect

The piezoresistive effect refers to the phenomenon in which the electrical resistivity of semiconductor materials undergoes significant changes when subjected to stress. The physical essence of this phenomenon lies in the deformation of the semiconductor lattice structure caused by stress, leading to changes in the band structure and subsequently affecting the mobility and scattering probability of charge carriers. Specifically, the change in lattice spacing under stress will alter the bandgap width, causing carriers to scatter from one energy valley to another, resulting in a change in carrier mobility and ultimately a change in resistivity.

The strength of the piezoresistive effect is usually characterized by the piezoresistive coefficient π, defined as the relative change in resistivity under unit stress. The piezoresistive effect has anisotropic characteristics, and the change in resistivity varies when stress and current are applied in different directions. For example, when measuring N-type silicon at room temperature, the piezoresistive coefficient π 11 is 102.2 × 10 ⁻¹ m ²/N when stress is applied in the (100) direction and current is passed in this direction, while the piezoresistive coefficient π 12 is 53.7 × 10 ⁻¹ m ²/N when current is passed in the (010) direction. This anisotropy requires the selection of appropriate crystal orientation and current direction for the design of piezoresistive sensors based on specific application scenarios.

三、 Working principle of piezoresistive sensor

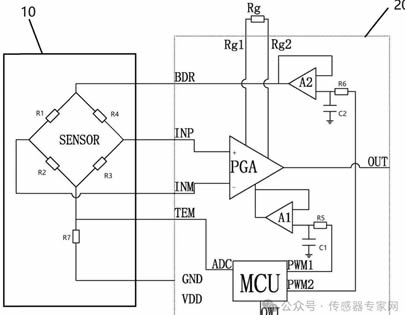

1. The piezoresistive sensor is based on the piezoresistive effect, and an equivalent resistance is diffused on a single crystal silicon substrate through integrated circuit technology to construct a Wheatstone bridge. Its core structure includes monocrystalline silicon film, diffusion resistor, leads, and amplification circuit. When the sensor is immersed in a pressure medium, the medium pressure is transmitted to the semiconductor core through the corrugated diaphragm and silicone oil, causing elastic deformation of the silicon diaphragm. Due to the piezoresistive effect, the diffusion resistance value on the diaphragm changes, causing the bridge to lose balance and output a voltage signal proportional to the stress.

2. Specifically, the workflow of a piezoresistive sensor is as follows:

3. 1. Stress transmission: The medium pressure acts on the corrugated membrane and is transmitted to the semiconductor core through silicone oil.

4. 2. Resistance change: After the silicon film is compressed, the resistance of the diffusion resistor changes, and the bridge loses balance.

5. 3. Signal amplification: The weak voltage signal output by the bridge is amplified by an amplifier and calibrated with standard pressure before it can be used for pressure detection.

四、 Technical advantages of piezoresistive sensors

Piezoresistive sensors play an important role in many application fields due to their excellent performance characteristics:

1. High sensitivity: It can accurately perceive small pressure changes, with extremely high pressure resolution, and can detect micro pressures like blood pressure.

2. Compact size and easy integration: processed using integrated circuit technology, with small structural dimensions and light weight, it can be easily embedded into various small devices.

3. Good stability and high reliability: After hundreds of thousands of fatigue tests, the performance remains unchanged, with high comprehensive accuracy and long service life.

4. Good dynamic characteristics: response frequency up to 10 ³~10 ⁵ Hz, capable of measuring pulsating pressure of tens of kilohertz.

5. Temperature sensitivity: Due to the use of semiconductor material silicon, the sensor is sensitive to temperature. If temperature compensation is not used, the temperature error will be large.

五、 Engineering Application of Piezoresistive Sensors

Piezoresistive sensors have shown broad application prospects in multiple fields:

1. Industrial automation: used on the production line to monitor fluid pressure, ensuring the stability and safety of the production process.

2. Aerospace: Used to measure the airflow pressure distribution of helicopter wings, dynamic distortion of engine air intakes, etc., with a working temperature of over 500 ℃.

3. Biomedical: An injection needle type pressure sensor with a diffusion silicon film as thin as 10 microns and an outer diameter of only 0.5 millimeters has been developed for measuring pressure in cardiovascular, intracranial, urethral, and other areas.

4. Petrochemical industry: used for measuring explosion pressure and shock waves, vacuum measurement, etc.

5. Automotive Engineering: Monitor and control the performance of automotive engines, such as measuring oil well pressure, direction finding while drilling, and detecting fault points in underground sealed cables.

六、 Technical Challenges and Future Prospects of Piezoresistive Sensors

Although piezoresistive sensors have many advantages, their development still faces some technical challenges. For example, the piezoresistive coefficient varies with temperature, leading to zero drift and sensitivity drift in the sensor. To solve this problem, a constant current source or a series diode in the power circuit of a bridge can be used for compensation. In addition, with the development of new materials and technologies, the performance and stability of piezoresistive sensors are expected to be further improved.

Looking ahead, piezoresistive sensors will play a more important role in fields such as the Internet of Things and intelligent manufacturing. For example, in the field of the Internet of Things, piezoresistive sensors can be an important component of smart devices, enabling real-time monitoring and data analysis of the environment; In the field of intelligent manufacturing, piezoresistive sensors help improve the automation and intelligence level of production lines.

七、 Conclusion

The piezoresistive effect, as a unique physical phenomenon in semiconductor materials, provides a highly sensitive solution for sensor technology. Piezoresistive sensors, with their excellent performance characteristics, have shown broad application prospects in various fields such as industrial automation, aerospace, biomedical science, etc. With the continuous advancement and innovation of technology, piezoresistive sensors are expected to bring us more exciting breakthroughs and convenient experiences.

Source: Sensor Expert Network