Micro pressure sensors have become indispensable measurement tools in many industries due to their high precision, high sensitivity, and wide range of applications. This article will delve into the working principle, diverse application scenarios, and range of micro pressure sensors, demonstrating the important role of this technological product in promoting social progress and industrial upgrading.

Working principle of micro pressure sensor

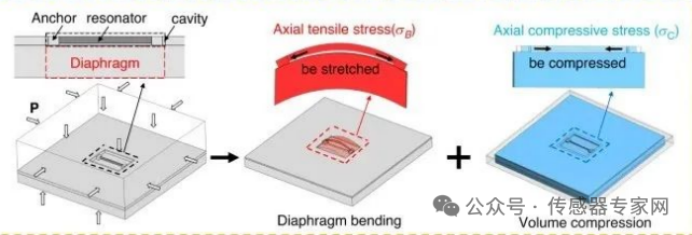

The working principle of a micro pressure sensor is based on a simple yet sophisticated physical process. When the pressure of the measured medium directly acts on the diaphragm of the sensor, the diaphragm will produce a small displacement proportional to the pressure of the medium. This displacement subsequently causes a change in the resistance inside the sensor, which is then detected through electronic circuitry and converted into a standard signal output corresponding to the pressure. This process not only achieves pressure measurement, but also ensures the accuracy and reliability of the measurement results.

Specifically, micro pressure sensors typically consist of sensitive components, conversion components, and signal processing circuits. Sensitive components are the parts that directly sense the measured pressure, such as diaphragms; The conversion component converts the perceived pressure changes into electrical signals; The signal processing circuit is responsible for amplifying, filtering, and calibrating these electrical signals, ultimately outputting a standard signal that can be used for subsequent processing.

Application scenarios of micro pressure sensors

1. Healthcare field

In the field of healthcare, micro pressure sensors are widely used for monitoring vital signs. For example, in devices such as blood pressure monitors, ventilators, and infusion pumps, micro pressure sensors can monitor patients' blood pressure, respiratory rate, and infusion pressure in real time, providing accurate data support for medical professionals to ensure timely and effective treatment for patients.

2. Industrial automation

Industrial automation is another important application area of micro pressure sensors. On the production line, micro pressure sensors are used to monitor and control the pressure of various fluids and gases, ensuring the safety and efficiency of the production process. For example, in liquid pipelines and hydraulic systems, micro pressure sensors can monitor pressure changes in real time to prevent safety accidents such as leaks and explosions.

3. Automotive industry

In the automotive industry, micro pressure sensors also play a crucial role. They are used to monitor key parts of the vehicle, such as the braking system, tire pressure, exhaust system, and engine pressure, to ensure the safety and performance of the vehicle. Meanwhile, in intelligent driving systems, micro pressure sensors can also work in conjunction with other sensors to provide more comprehensive and accurate driving assistance information.

4. Aerospace

In the aerospace field, micro pressure sensors also play an important role. They are used to monitor the air pressure and altitude of aircraft, ensuring flight safety. In space exploration missions, micro pressure sensors can also measure atmospheric pressure in outer space, helping scientists understand the properties and composition of planetary atmospheres.

5. Environmental monitoring

In the field of environmental monitoring, micro pressure sensors are used to measure parameters such as soil pressure, water pressure, and atmospheric pressure to monitor changes and trends in the natural environment. This is of great significance for fields such as meteorological forecasting, geological exploration, and water resource management

6. Consumer Electronics

With the continuous development of technology, micro pressure sensors are gradually penetrating into the field of consumer electronics. For example, in smartphones and tablets, pressure sensors can be used to detect user gestures and touch operations, providing a more accurate and convenient user experience.

Source: Sensor Expert Network. If there is any infringement, please contact us for deletion