Sensor technology, as a key link in information acquisition, is undergoing unprecedented changes. Among them, MEMS (Micro Electro Mechanical Systems) sensors, as representatives of emerging technologies, are gradually replacing traditional sensors and becoming an important force in promoting technological progress and industrial upgrading. This article will delve into the reasons why MEMS sensors replace traditional sensors, revealing the technological logic and market drivers behind this trend.

The limitations and challenges of traditional sensors

Traditional sensors, such as temperature sensors, pressure sensors, and light sensors, are mainly based on physical and chemical principles, which perceive and convert sensing signals into electrical signals through physical or chemical changes. These sensors perform well in accuracy, stability, and reliability, and are widely used in fields such as industrial control, safety monitoring, and medical equipment. However, with the continuous development of technology, traditional sensors are facing increasing challenges in miniaturization, power consumption, integration, and cost. Traditional sensors are usually bulky and require more space for installation, which to some extent limits their application in small or embedded systems. In addition, traditional sensors have high power consumption, which is not conducive to the long-term use of battery powered devices. In terms of integration, traditional sensors often focus on a single measurement function, making it difficult to achieve multifunctional integration. Meanwhile, the high manufacturing cost of traditional sensors also limits their widespread application in certain fields.

The Rise and Advantages of MEMS Sensors

MEMS sensors are a relatively new sensor technology that utilizes microelectronic manufacturing techniques to manufacture tiny mechanical structures for detecting and measuring various physical quantities. The working principle of MEMS sensors covers fields such as micro mechanical structures, microfluidics, and microelectronics, and has significant advantages in miniaturization, low power consumption, multifunctionality, and low cost. Firstly, MEMS sensors are compact in size and can operate in very limited spaces, making them suitable for various embedded systems and mobile devices. The miniaturization feature of MEMS sensors significantly reduces weight and energy consumption, while improving response speed and sensitivity. Secondly, MEMS sensors integrate multiple measurement functions such as accelerometers, gyroscopes, pressure sensors, and gas sensors, enabling multifunctional integration and meeting the needs of complex application scenarios. In addition, due to the maturity of microelectronics manufacturing technology, the manufacturing cost of MEMS sensors is relatively low, which helps to promote their application fields.

Reasons for MEMS replacing traditional sensors

The main reasons why MEMS sensors replace traditional sensors are as follows:

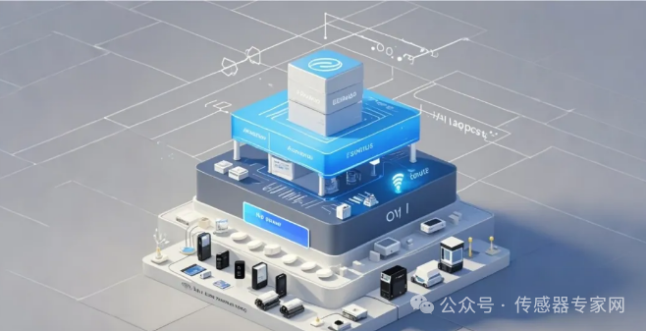

1. Technological progress and market demand: With the rapid development of emerging markets such as the Internet of Things, smart homes, and smart wearable devices, the demand for miniaturized, low-power, and highly integrated sensors has sharply increased. MEMS sensors, with their unique technological advantages, perfectly meet these market demands.

2. Cost effectiveness: MEMS sensors adopt mass production methods, which can simultaneously manufacture hundreds or thousands of micro mechanical components or complete MEMS on a single silicon wafer, greatly reducing production costs. This gives MEMS sensors a significant price advantage, which helps them to be quickly promoted in the market.

3. Multidisciplinary intersection and innovation capability: MEMS technology involves multiple disciplines such as electronics, mechanics, materials, physics, chemistry, and biology, and has strong innovation capabilities. With the continuous advancement of technology, MEMS sensors will continue to expand into new application areas, achieving more intelligent and efficient perception and control.

4. Policy Support and Industrial Rise: The Chinese government is committed to enhancing the independent innovation capability of the MEMS industry and gradually narrowing the gap with the international community through various policies and financial support. As one of the world's largest consumer electronics markets, China will become an important stage for the MEMS industry.

Outlook for the Future: Prospects and Challenges of MEMS Sensors

Looking ahead, MEMS sensors will play an important role in more fields. In the field of consumer electronics, with the popularization of smart homes and the Internet of Things, MEMS sensors will become a key component of smart home devices, achieving a more intelligent and convenient living experience. In the automotive industry, MEMS sensors will be widely used in airbags, electronic stability systems, and autonomous driving technology to improve the safety and intelligence level of vehicles. In the medical field, MEMS sensors will be used in medical monitoring equipment and surgical instruments, providing strong support for the development of the medical industry. However, the development of MEMS sensors also faces some challenges. Firstly, the technical threshold is high, the research and development cycle is long, and continuous investment in research and development funds and technical talents is required. Secondly, the packaging and testing technology of local enterprises is not yet mature enough, leading to a heavy reliance on imported products. In addition, the application scenarios of MEMS sensors are complex and diverse, requiring customized design and production for different application requirements.

Conclusion: MEMS sensors lead technological change

In summary, replacing traditional sensors with MEMS sensors is the trend. With its advantages of miniaturization, low power consumption, multifunctionality, and low cost, MEMS sensors will play an important role in more fields, promoting technological progress and industrial upgrading. In the future, with the continuous advancement of technology and the expansion of the market, MEMS sensors will become a key focus of intelligent development