With the rapid development of technology, various sensor technologies continue to emerge, providing strong support for automation and intelligence in various fields. Among these sensors, grayscale sensors have become a shining pearl in the field of modern technology with their unique measurement capabilities and wide application scenarios. This article will provide a detailed introduction to the definition, structure, working principle, and application of grayscale sensors, leading you to a deeper understanding of this cutting-edgetechnology.

Definition of Grayscale Sensor

A grayscale sensor, also known as a grayscale sensor, is an electronic component used to measure the intensity of light and convert it into a digital signal. It can calculate the gray level of light by comparing the brightness of the received light with a preset standard value. The grayscale level is related to the contrast of the object surface or scene, therefore, using a grayscale sensor can quantify the brightness of objects in the scene and output corresponding grayscale values.

Structure of grayscale sensor

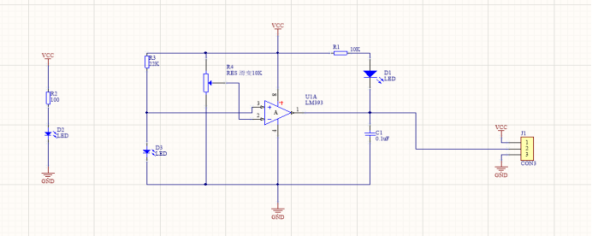

The structure of a grayscale sensor mainly includes photosensitive elements, filters, amplification circuits, interface circuits, and other parts. Among them, the photosensitive element is the core part of the grayscale sensor, commonly used are photodiodes and photoresistors. Filters are used to enhance the sensitivity of grayscale sensors to specific wavelengths of light, thereby increasing the sensitivity of the sensor. The amplification circuit is used to enhance the weak electrical signal generated by the photosensitive element and amplify it to an appropriate amplitude range. The interface circuit enables the grayscale sensor to communicate and exchange data with other electronic devices.

Working principle of grayscale sensor

The working principle of grayscale sensors is based on the photoelectric effect. When light shines on the surface of the object being measured, different colors will have different effects on the absorption and reflection of light. Grayscale sensors use photosensitive elements to sense the reflection of light. When the sensor is working, the light source will shine on the surface of the object being measured, and the object will reflect some of the light. After the light passes through the photosensitive element, the photosensitive element will generate a corresponding current signal. The magnitude of this current signal is directly proportional to the grayscale value of the surface of the object being measured. The sensor converts the current signal into a digital signal and outputs it to the control system for further processing. In order to obtain more accurate grayscale values, grayscale sensors usually use special optical filters to remove interference from light. Filters can only pass light of specific wavelengths, allowing sensors to only receive light signals of specific colors, thereby improving measurement accuracy.

Application of Grayscale Sensor

Grayscale sensors have a wide range of applications in various fields, including image processing, robot vision, lighting control, print quality control, automated production, and environmental monitoring.

1. Image processing and computer vision: Grayscale sensors can be used in image processing and computer vision systems to analyze and process images by measuring the grayscale values of object surfaces. They can help detect edges in images, recognize objects, measure brightness, and more.

2. Robot vision: In the field of robot vision, grayscale sensors are commonly used to detect and track moving objects. Through grayscale sensors, robots can make real-time decisions and reactions based on the grayscale level of objects, achieving higher levels of autonomy and accuracy.

3. Lighting control: Grayscale sensors can be used to automatically adjust the brightness of indoor or outdoor lighting systems. By monitoring the lighting intensity of the surrounding environment in real-time, the grayscale sensor can adjust the brightness of the lights according to demand to provide suitable lighting conditions.

4. Print quality control: In the printing industry, grayscale sensors can be used to detect the density of ink dots on printed paper, thereby achieving control over print quality.

5. Automated production: Grayscale sensors also have important applications on automated production lines. For example, in the field of food processing, grayscale sensors can be used to detect the clarity and readability of labels or QR codes on food packaging bags to ensure product quality and traceability.

6. Environmental monitoring: Grayscale sensors can also be used for environmental monitoring, such as measuring atmospheric pollutant concentrations, soil moisture, water turbidity, etc.

summary

As an important photoelectric sensor, grayscale sensors play a crucial role in multiple fields due to their ability to accurately measure light intensity and convert it into digital signals. By delving into the definition, structure, working principle, and application of grayscale sensors, we can better utilize this cutting-edge technology to promote the automation and intelligent development of various fields. In the future, with the continuous advancement of technology, grayscale sensors are expected to demonstrate their unique value and potential in more fields.