In the United States alone, approximately 100000 traffic accidents are caused by human factors such as drowsiness or fatigue each year. Automotive biosensors can be used to help maintain safe driving by providing early detection of health issues, preventing fatigue related accidents, and assessing stress and emotional states. Various methods have been explored to measure physiological markers of fatigue and alertness in automotive environments, including electrophysiological, inertial behavior related, and visual approaches. However, these methods are difficult to reliably and unobtrusive capture physiological markers in dynamic environments, such as in automotive or aviation applications where significant vibrations occur. The electrodes have been integrated onto the surface of the steering wheel to obtain electrophysiological markers of inattention, but this method requires stable skin contact, which is difficult to achieve. Alternatively, in some cases, the use of cameras as a monitoring method is promising, but they rely on ambient lighting and may pose potential privacy concerns.

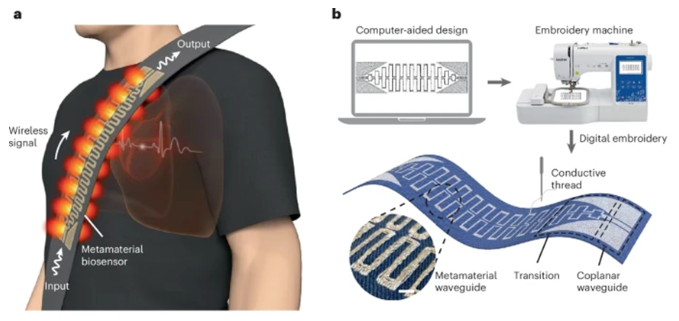

Wireless sensors may provide inconspicuous fatigue and attention detection in vehicle environments. They are less sensitive to environmental noise (such as variable lighting conditions) and can protect user privacy. However, obtaining high-quality physiological parameters in dynamic environments including vibration, random body movements, and multiple passengers remains challenging due to motion artifacts and signal interference caused by multipath reflections in enclosed cabin environments. Recently, Professor He Siyuan from the National University of Singapore collaborated with a team led by Tian Xi from the Shenzhen International Graduate School of Tsinghua University to report on a metamaterial biosensor. It can capture cardiopulmonary signals in a dynamic environment without direct contact with the body. This biosensor is made of digital embroidery, can be integrated with seat belts, and can detect physiological movements through near-field interaction between wireless signals and the body.

Using conductive wires and computer-aided digital embroidery to manufacture biosensors, this soft textile sensor can fit the body, adapt to user activities, and integrate with existing seat belts. Biosensors can continuously monitor heart rate (HR) and respiration at various positions on seat belts, including shoulder and waist straps, and maintain performance for different clothing materials and thicknesses. The embroidery metamaterial system was tested in an airline cabin simulator for itsability to detect a range of human activities and verify its ability to distinguish between sleep and wakefulness stages. Biosensors can also reliably extract respiratory and heartbeat signals and maintain accuracy in challenging dynamic environments.

Design of Biosensors: In order to overcome the signal attenuation caused by relative motion, a metamaterial is integrated using a wire harness mechanically coupled with the body as the substrate. This metamaterial can achieve highly sensitive detection of physiological movements through near-field interaction between wireless signals and the body. Choosing digital embroidery with conductive wires as the manufacturing strategy, as it can accurately produce complex periodic patterns on almost any existing fabric substrate. This metamaterial is composed of a hollow comb shaped structure that supports the transmission of small wavelength surface waves through a low fill factor. The structure propagates wireless signals as Deception Surface Plasmon (SSP) polaritons, whose wavelengths are compressed to about a quarter of the free space wavelength. These highly restricted near-field sensing modes provide robustness against potential interference, such as driver posture changes and multi passenger clutter. Dispersion relation analysis is used to design the geometric parameters of the unit cell to obtain the required surface mode characteristics within the 2.4-2.5 GHz operating frequency band. When the fill factor q decreases from 8 mm to 1 mm, the wavenumber β at 2.4 GHz increases from 0.48 π to 0.65 π rad cm-1, indicating stronger field confinement and wavelength compression. In addition, the filling factor can be adjusted to support the application of surface modes ranging from 0.49 π to 0.59 π rad cm − 1 on different textile substrates.

In order to achieve efficient wave vector conversion from metamaterial structures to 50 Ω coplanar waveguides (CPW), a transition cross-section compatible with traditional microwave connectors was designed. The impedance matching transition composed of gradient corrugated hollow strips and expanded grounding improves transmission efficiency by more than 4 dB and reduces conversion losses between metamaterial waveguides and CPW. On the other hand, the transmission loss of metamaterial biosensors is determined by the electrical conductivity of textiles, which can be adapted by changing thefilling factor. To ensure compatibility with embroidery production and maintain sub wavelength compression, q=2 mm was chosen to keep transmission loss at 0.25 dB cm-1. The full wave simulation of metamaterial biosensors on computational models demonstrates the wavelength compression and energy limitation of the biosensor surface. These features can enhance wireless interaction with the body, utilizing changes in tissue characteristics caused by cardiopulmonary activity to more effectively regulate the propagation phase, especially when biosensors are integrated into seat belts located in front of the body. The transmission signal propagates along the metamaterial structure in the form of surface waves, and converts the changes in tissue boundaries and dielectric properties into phase modulation.

Source: Sensor Expert Network. Reproduction of this article is to convey more information. If there is any infringement, please contact us for deletion