Huazhong University of Science and Technology in collaboration with Nanyang Technological University in Singapore: Developing an injection ultrasound sensor for wireless monitoring of intracranial signals

This article proposes a new biomaterial, matagel, which can be used for in vivo monitoring. Matagel not only has mechanical strength similar to intracranial, but also can completely degrade in vivo within 4 months. It can also use ultrasound monitoring to respond to various stimuli, reflecting changes in physiological status in the body, providing new solutions for clinical in vivo implantation research, and promoting the green and safe development of the medical industry.

What is metal?

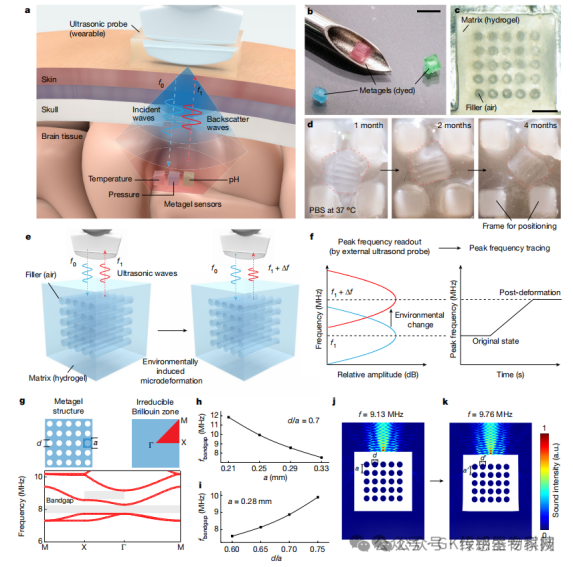

Metagel consists of 25 closed and straight air ducts (200 µ m in diameter and 1500 µ m in height) arranged in a tough hydrogel matrix. A mold with 25 straight rods was designed and printed using a 3D printer. In order to improve the manufacturing efficiency of metagel, put the four molds together, pour the pre gel solution, and start crosslinking.Next, the hydrogel sample with the opening channel is carefully separated from the mold, and finally the opening channel is packaged with pre gel solution to generate super gel, and soaked in PBS with pH 7.4 for at least 1 hour until the swelling equilibrium state is reached. The prepared metagel is responsive to various stimuli (pressure response, temperature response, ph response, etc.), based on which metagel is used to monitor the environmental physiological state in the body.

WHY - Advantages of using wireless implantation for intracranial physiological monitoring?

Direct and precise monitoring of intracranial physiology is of great significance for describing injury, prognosis, and avoiding diseases. The use of wired clinical instruments with percutaneous wires is accurate, but during the removal process, it is susceptible to infection, patient mobility difficulties, and potential surgical complications.Compared with traditional clinical instruments, wireless implantable sensors provide a promising solution for intracranial monitoring. Wireless implantable devices provide greater operational freedom and greatly reduce the risk of infection. Currently, wireless implantable sensors mainly use near-field communication, inductively coupled or ultrasonic communication, and can be used to monitor human parameters, including pressure, flow rate, temperature, and pH value.

HOW - The research team has proposed a new implantable biodegradable ultrasound material, metagel, and monitored data on various intracranial parameters through metagel.

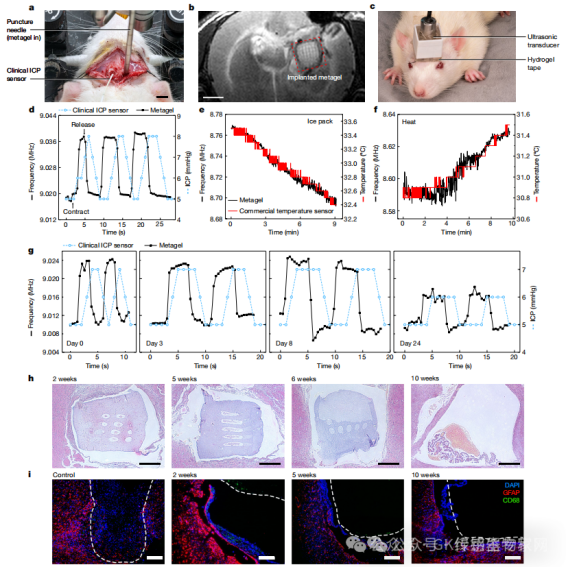

In this work, the author proposed a new kind of ultrasonic sensing material of the super medium layer, which is called the miniaturized element structure hydrogel, which is a variety of soft acoustic metamaterials and can be completely degraded in the organism. Using metagel as an implant, rich intracranial physiological signals (pressure, temperature, pH, and flow rate) can be wirelessly monitored through an external ultrasound probe (Figure 1a).Design a cube with a metagel of 2 × 2 × 2 mm3 and insert it into the body with the assistance of a traditional puncture needle (Figure 1b, c). The metagel naturally degrades within 4 months in a PBS solution at 37 ℃ (Figure 1d).

Metagel perceives intracranial environments based on micro deformations caused by the environment. It consists of a hydrogel matrix and a periodic gas column to form soft phononic crystals with adjustable acoustic reflection spectra (Fig. 1e). This structural design endows the metagel with extraordinary acoustic reflection characteristics.When ultrasound is emitted (with a peak frequency of f0), the metagel reflects these at the peak frequency f1. Changes in the intracranial environment cause micro deformation of the bone and alter the frequency of the reflection peak (f1+Δ f). By performing stimulation response functionalization (pressure response, temperature response, ph response, etc.) on the hydrogel matrix, metagel can track environmental changes by tracking the peak frequency shift of reflected ultrasound (Fig. 1f).

The author understands how the design of the element plate affects the ultrasonic reflectivity by calculating the band structure of the element plate. When the lattice constant is a and the filler diameter is d, the bandgap of the metagel can be calculated by solving the eigenvalue equation of a single element with Bloch boundaries. At a=0.28 mm and d=0.196 mm, the sound band gap of the metagel is centered around 8.2 and 9.2 MHz (Figure 1g). When ultrasonic waves with frequencies within these bandgap ranges are transmitted to the plate, most of the energy will be reflected, making it easy to distinguish the plate through ultrasonic imaging.The bandgap of the metagel depends on a and the filling ratio (FR=d/a) (Figure 1), therefore, the changes in a and FR caused by metagel deformation are manifested as bandgap changes. The finite element simulation of the sound field can display the frequency shift of the reflection peak caused by the deformation of the metagel. The peak frequency of the reflected sound wave from the undeformed element plate is about 9.13 MHz (Figure 1j), which is consistent with the bandgap calculation in Figure 1g. Due to changes in the physiological environment, the element board undergoes deformation, and the peak frequency of the reflected wave shifts to 9.76 MHz (Figure 1k).