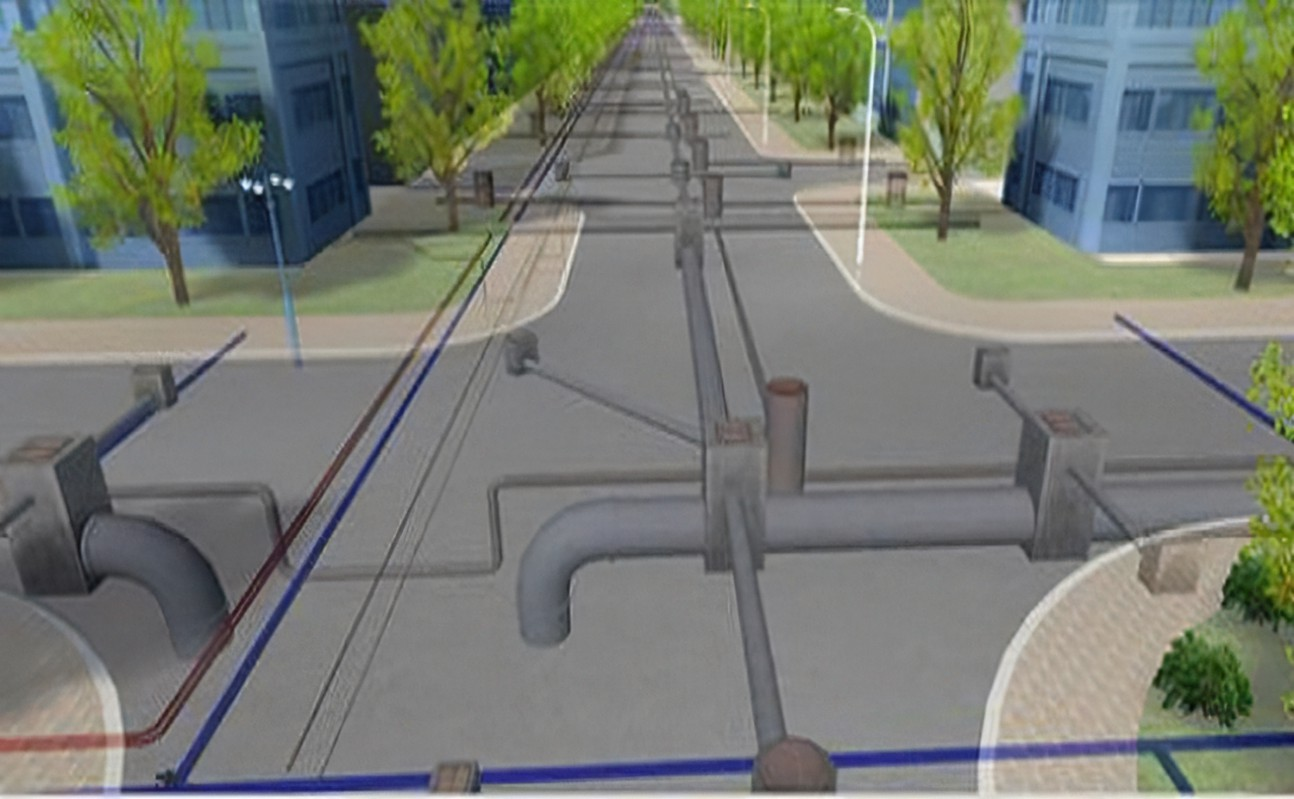

1. Underground pipeline network, background of underground monitoring industry

The underground pipeline network is the lifeline of the city. In recent years, with the rapid development of cities, some places have experienced safety accidents such as water supply, drainage, gas, and heat pipeline leaks due to the relatively backward management level and technical means of underground pipeline networks, directly affecting the safety of people's lives and property and the safety of urban operation. In 2013, the State Council issued the "Opinions on Strengthening Urban Infrastructure Construction" (Guofa [2013] No. 36), and in 2014, the General Office of the State Council issued the "Guiding Opinions on Strengthening the Management of Urban Underground Pipeline Construction" (Guobanfa [2014] No. 27), emphasizing the conduct of urban underground pipeline surveys, the establishment of a comprehensive management information system for underground pipelines, meeting the needs of urban planning, construction, operation, and emergency response, and ensuring the safety of urban operation. In 2014, the Ministry of Housing and Urban Rural Development and six other departments jointly issued a notice to deploy and promote the survey of urban underground pipelines and the construction of comprehensive management information systems.

In the context of the promotion of the national "Internet plus" development strategy, there is no doubt that using the "Internet plus" thinking to carry out the informatization construction of urban pipe network safety operation management will become a new important topic. At present, modern information technologies such as Geographic Information Systems (GIS), Building Information Modeling (BIM), Internet of Things, cloud computing, big data, and Beidou high-precision positioning have been utilized in developed regions of China to construct safety operation monitoring systems for urban management. These systems have played an extremely significant role in environmental governance, transportation, public safety, emergency relief, and municipal law enforcement.

By utilizing the construction experience of safety operation monitoring systems in these areas and implementing IoT, real-time, and intelligent management through urban pipeline networks, the management level of urban pipeline network safety operation guarantee can be greatly improved, work efficiency can be enhanced, energy conservation and consumption reduction can be achieved, and significant economic and social benefits can be achieved.

2. The main purpose and problems to be solved in the underground pipeline network and underground monitoring industry

Integrate data on the safe operation of urban underground pipelines, coordinate the construction of underground pipeline safety operation monitoring systems with various professional pipeline management, digital city management, urban construction archives, and smart city management information platforms, and solve problems such as business segmentation and information silos.

Focusing on the construction of accident prevention, disaster prevention, and emergency response capabilities for important pipelines, key areas, and key parts, expanding the scope and content of underground pipeline monitoring, and improving the level of urban planning, construction, and management services.

Establish a working mechanism led by the government, coordinated by departments, and linked by pipeline property rights units, build a management system that coordinates comprehensive monitoring, industry monitoring, and regional monitoring, and comprehensively implement the operation and maintenance, safety investigation, and hidden danger elimination of underground pipeline networks.

3. Underground pipeline network, different types of sensors involved in the underground monitoring industry

(1) Drainage pipe network monitoring system: The drainage pipe network monitoring system realizes the monitoring and management of basic information and operating status of urban drainage pipe network online monitoring facilities. The monitoring device can collect data such as pipe network pressure, flow rate, and flow direction, support regular reporting and monitoring data over limit reporting, and can query real-time liquid level, flow rate, and other information of pipe network monitoring points. The monitoring device is mainly used for flow monitoring of domestic sewage, combined sewage or rainwater pipe networks. There are multiple composite technology sensors to choose from, and the combination of these monitoring technologies provides users with a multi-purpose monitoring platform.

(图片来源:网络)

(2) Drainage pump station monitoring system: The drainage pump station monitoring system monitors the start stop status, protection status, current, and voltage of each drainage pump in each pump station; Monitor the working status of the grid machines in each pumping station; Monitor the liquid level, cumulative drainage volume, and concentration of harmful gases in the drainage tanks of each pumping station; Monitor the security alarm information of each pumping station.

(图片来源:网络)(Image source: Online)

(3) Water accumulation point monitoring system: Through the sensors carried by the equipment inside the manhole cover, real-time monitoring and management of the manhole cover can be carried out 24/7, including real-time alarms for abnormal posture changes such as lifting, translation, and large angle vibration of the manhole cover, ensuring that the manhole cover is in normal condition and timely handling of special events. At the same time, it supports electronic map distribution display; The backend server database can achieve multiple information queries and management. Intelligent monitoring of manhole covers will bring the following benefits: effectively preventing external network intrusion, timely stopping manhole cover theft, timely detecting broken manhole covers, and facilitating quick positioning and alarm response.

(4) Drainage manhole cover monitoring system: Through the sensors carried by the equipment inside the manhole cover, the manhole cover can be monitored and managed in real-time around the clock, including real-time alarms for abnormal posture changes such as lifting, translation, and large angle vibration, ensuring that the manhole cover is in normal condition and timely handling of special events. At the same time, it supports electronic map distribution display; The backend server database can achieve multiple information queries and management. Intelligent monitoring of manhole covers will bring the following benefits: effectively preventing external network intrusion, timely stopping manhole cover theft, timely detecting broken manhole covers, and facilitating quick positioning and alarm response.

4. The sensor products of Senser Technology involved in the underground pipeline network and underground monitoring industry

(1) Recommended model for pipeline and pump vibration monitoring: 310A. Performance features: sturdy, durable, corrosion-resistant, metal sealed, welded, shell isolated, EMI/RFI shielded, and impact resistant.

(2) Recommended pressure sensor model P1503 Performance features: Standing height vibration, 1.5% total error band, integrated cable, ASIC temperature process, applied in automation and control testing and measurement, energy management, heavy industry, plastic and alloy injection, etc.

(3) The characteristics of the IN-LDG state monitoring system include the ability to exchange data with various systems, local HIM display system (indication value, alarm), PLC system (indication value, alarm, simple diagnosis), CMS system (indication value, alarm, raw data, FFT analysis, fault diagnosis), and various big data processing and analysis systems within the factory (indication value, diagnostic results). The IN-LDG intelligent vibration transmitter has strong data processing capabilities and can meet the vibration monitoring needs of different types of equipment.

For more application case sharing, please consult the professional sensor service team of Senther Technology.